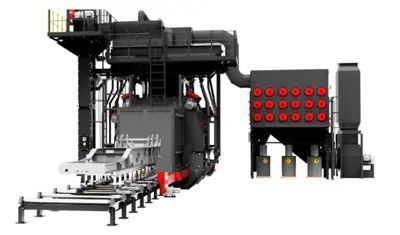

Machine suitable for shot blasting of beams, profiles, angles and pipes equipped with complete abrasive recovery system, including a bucket elevator, abrasive air wash separator, dust collector, roller conveyor and electrical components.

o Maximum passage section of pieces 31” (0.8 m) W x 40” (1 m) H

o Effective shot blasting: 24” (0.6 m) W x 31” (0.8 m) H

o Length: 10 ft. (3 m) to 50 ft. (15 m)

Blasting cycle

The operator loads the profiles onto the entrance conveyor. Parts is fed into the entrance of the machine, it passes through the Blast Chamber, parts are them unloads at exit of machine chamber.

Inside the chamber, parts are blasted by four-six (depending on profiles) turbines. The abrasive falls into the collection hopper mounted underneath where it flows into the foot of the bucket elevator to be carried up to the abrasive reclamation unit to be sieved and cleaned before going into the abrasive silo mounted underneath. Then the abrasive is re-fed to the turbines via the control valves. The blast chamber is sealed against stray abrasive by rubber sealing.

Highly Customizable (Build-to-Order)

We use cookies to improve your experience. Privacy Policy.